Case Study: SSI Fabricated

Division of Hellan Strainer Company

SSI Fabricated, a Division of Hellan Strainer Company fabricates a wide array of ASME Certified strainers and pressure vessels. SSI Fabricated specializes in custom fabricated vessels for a variety of applications and has been in operation since the early 1990's.

The Business Challenge:

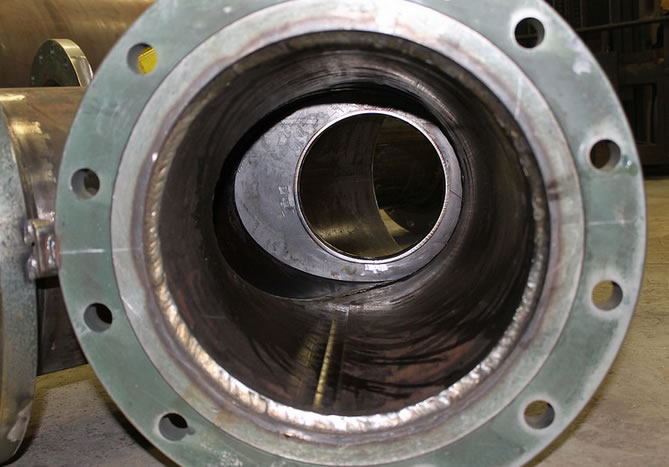

This project included building 48" steam separator vessels with 24" inlet/outlet nozzles, custom designed for a Utilities Plant. This project included a requirement for SSI to provide ASME Certified "U Stamped" vessels. In our Project Gallery below it is clear that SSI provides high-quality fabrication, ASME stamped for consistency and quality control.

David Branscum

Production Manager, GM of SSI

David has over 25 years of experience with industrial manufacturing and fabrication. He started right out of high school at age 17, doing fabrication in the field. After working in a shop for several years, David returned to school, earning a degree in Business.

David worked for SSI from 1992-2000. After a few years pursuing other opportunities, he returned to SSI in 2011 in his current management position. David is in charge of all fabrication, maintenance and building of equipment for the company.

The Watts Benefit:

"We have only been using the Watts W-484 System with the 3D CAD Software for just over 8 weeks," said Branscum. "I would estimate that we are saving around 160 man hours per week since getting the Watts System. That is equivalent to 4 pipe fitters, and we may be saving more time than I have estimated."

"We are still finding out what we can and cannot do with this new System," continued Branscum, "but for the most part our Watts machine will handle 2" thru 48" pipe or rolled plate - this gives us plenty of room for savings on almost any project.

We have already increased our production and accuracy with cutting and beveling our components. We have communicated the prospect of increased future production to our customers - they are really excited with the possibility of increased production and shorter turn-around times. Watts equipment helps us increase productivity which means fewer workers standing around with nothing to do."

3D Nesting Software

"The software makes the task of laying out everything by hand virtually effortless - fewer mistakes are made when you can see your 3D model. I have a couple of young guys right out of high school who are really into it. They picked up the software fast and love how they can make a couple of clicks with a mouse and turn out the same or better part than a 30 year veteran."

The Watts Difference:

"We were spending too much time cutting joints and prepping pipe," said Jeremy. "Prior to having the Watts machine in production it would take two full days with four men to cut, bevel and prep all the pipe pieces we needed for a project. Now we get the same amount of pipe cut, with perfect bevels, in six hours. There is no laying out the pipes, no chalk lines, no need for QA to check everything prior to cutting. The cuts are loaded into the pipe cutting software and the machine does the job."

ROI Cost Study Numbers

"Our initial cost study indicated that we would save enough in labor and materials to pay for the machine and the accessories in only two years," continued Jeremy Watts. "We are cutting around 50-80 vessels per month with 150-200 pipe cuts per month. The majority of our work is on vessels with nested pipe cuts."

"Now that we have been using the machine we are seeing a 10:1 ratio; what normally would take 10 hours with the old system of cutting and grinding by hand can be done in one hour. I initially figured a savings payoff for the whole purchase in only two years and from what we have already seen this looks like an accurate assessment."

|