Case Study:

Winger Companies

Winger Companies is a one-stop Mechanical / Electrical Contracting Company serving the Commercial and Industrial Markets. On the mechanical side Winger specializes in process piping, plumbing, refrigeration, fire sprinkler systems, HVAC systems, Sheetmetal design & fabrication, steel fabrication, millwright services, and maintenance services. Winger also focuses on Commercial and Industrial medium voltage electrical construction, low voltage data, security, and structured cabling, etc.

Winger Fabrication Shops - Cedar Rapids, Iowa

Winger Companies, established in 1942, is a fourth generation family-owned business and has grown to be the leader in mechanical construction for the Midwest region. Winger began as an equipment manufacturer and quickly added power plant construction, stretching its market reach to North Dakota, Nebraska, Wyoming, Missouri and Kansas.

Winger continued to push into new markets as our nation grew and expanded. As the space age developed Winger began to take on construction and installation of propellant skids for the Atlas, Titan and Minute Man missile systems for the Kennedy Space Center and the U.S. Government. In the 80's the company entered the agricultural and grain processing market while adding two new trades (Sheetmetal and Millwright services). Fast forward to the new millennium, Winger added Data Technology and Fire Sprinkler systems to complement its portfolio of Skilled Trades.

Winger Companies is a certified Veteran Owned Business.

Mike Smith, General Manager

Mike Smith joined Winger Companies in 2016 with close to 30 years of experience in the mechanical piping industry. Mike's expertise is in Pre-fabrication. His oversight of complex fabrication/piping projects has guided Winger ownership to invest over $1 Million in piping fabrication technology over the last 5 years.

As the General Manager, Mike is known for his, "Why can't that be fabricated" mentality which has led to a positive culture shift at Winger regarding prefabrication for piping projects. Mike also puts emphasis on team safety, team leadership and collaboration both internally and externally. Mike's leadership style ensures open communication throughout large projects, ensuring a smooth operation from start to finish.

Winger Companies entrusts Mike with some of their most critical and time sensitive projects, delivered on time and within budget. Mike has repeatedly proven his ability to lead the construction team through multiple multi-million dollar projects. His knowledge of piping has brought many innovations and improvements to Winger, including his push to use automation in pipe fabrication with the purchase of Watts machines.

The Business Challenge:

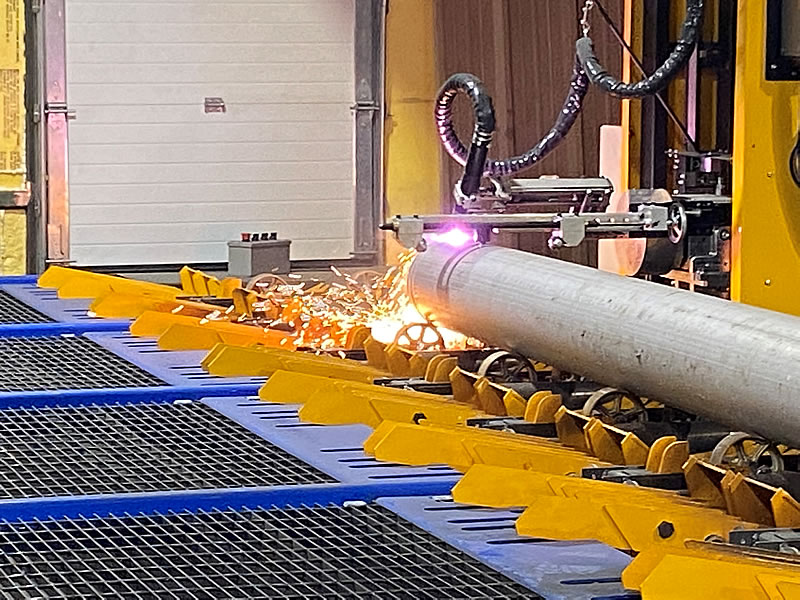

"Our fabrication projects had grown to the point where we needed to add automation to our processes in order to become more efficient," said Mike Smith. "We bought a Watts W-244 machine in 2015 - that gave us more ability to cut and bevel pipe up to 24" OD. We increased our finished fabrications while cutting the cost of both consumables and manhours."

"We continued to grow in our fabrication projects, both in volume and with projects calling for larger pipe," Smith continued. "In 2020 we purchased a second machine, a Watts W-364 capable of cutting up to 36" OD pipe. This machine went into our Cedar Rapids fabrication shop and further extended both our efficiency and our capabilities."

The Watts Solution:

The most pressing reason for Winger Companies to purchase the Watts machines was to gain efficiency. "We needed to become more productive with the same manhours and we needed to save on consumables," said Smith. "Where it took 25 minutes to lay out and cut an 8 inch pipe, the same cuts are done in only around 90 seconds with the automated machine. The Watts pipe profiling system allows us to make precise, uniform, clean cuts in a minimal amount of time. We are more efficient, spending less on prep time and less on manhours."

Winger Companies also purchased a conveyor system with the new W-364 machine: a 25 ft machine bed with an integrated powered conveyor. In addition, Winger purchased another 20 ft infeed conveyor and rack outside the building, enabling the pipe to be power-fed into the shop.

The Watts Difference:

"Due to labor shortages in the industrial fabrication industry, we needed a way to get more productivity with less manhours," Smith said. "Where it used to take two people to prep and mark up a pipe for a saddle cut, now the job only requires one person to input the numbers into the 3D-Profile Plus software and simply run the machine. Even the most complicated cuts can be done by one person, the machine operator."

"In addition, it used to take two people to move, stage and prep large pipe. Now, with the automatic infeed bed we can load pipe outside the building, convey into the building and right onto the machine bed. Prior to having the feeding racks we had difficulty loading heavy pipe - we had to use a crane which called for more workers. We are saving in manhour costs and we have increased the safety for our employees in all of our fabrications."

3D-Profile Plus Software and Watts Support

"The software with the input communication of the measurements, angles and outlets is very user-friendly. I can send numbers from my desk directly into the machine if I need to.

Watts support has also been good. Our machine operator likes how the support staff has working knowledge of fabrication and can offer more than just technical knowledge about the machine."